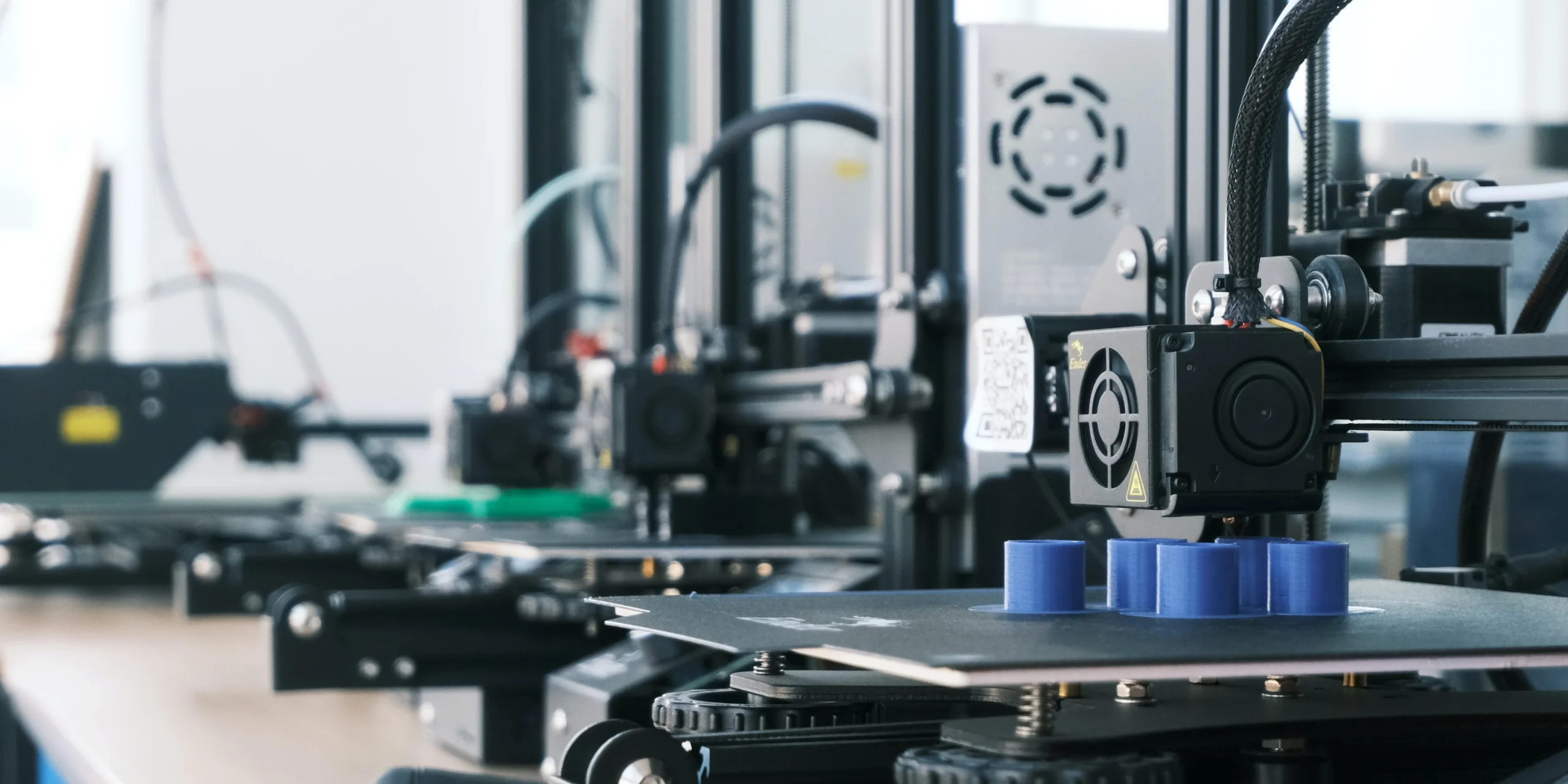

The manufacturing industry is undergoing a powerful transformation driven by digital technologies. Traditional manufacturing methods are no longer enough to meet today’s demand for speed, accuracy, and customization. This is where digital manufacturing comes in. By combining advanced software, automation, real-time data, and smart machines, digital manufacturing is reshaping how products are designed and produced. Two areas experiencing the biggest impact are CNC machining and rapid prototyping. These technologies are now faster, more precise, and more cost-effective than ever before. In this article, we will explore how digital manufacturing is changing CNC machining and rapid prototyping, its real-world applications, benefits, common mistakes, and what the future holds for manufacturers.

Leatherhead

Main Concept: Digital Manufacturing in Modern Production

Digital manufacturing is not a single tool or machine—it is a complete digital ecosystem that connects design, production, and quality control into one seamless workflow.

Explanation: How Digital Manufacturing Works with CNC Machining and Prototyping

At its core, digital manufacturing relies on data-driven decision-making. Engineers start with CAD (Computer-Aided Design) models, which are directly connected to CAM (Computer-Aided Manufacturing) software. This data flows into CNC machines, enabling automated toolpaths, precise cutting, and minimal human error.

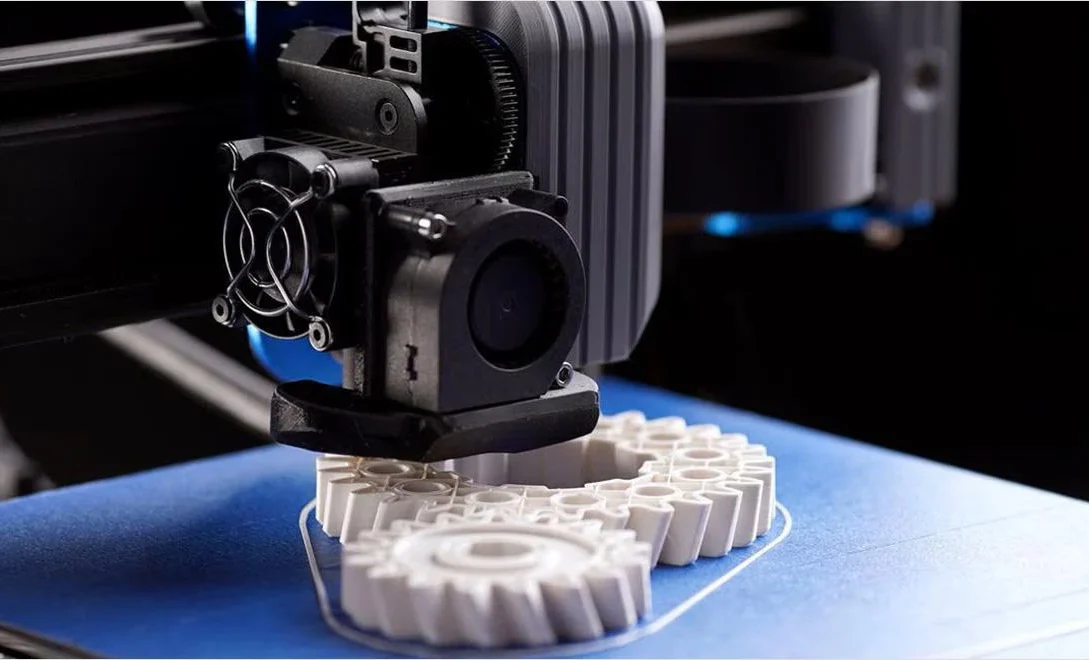

For rapid prototyping, digital manufacturing allows manufacturers to simulate designs before physical production. Errors can be identified early using virtual testing, saving both time and material. CNC machining plays a key role here by producing functional prototypes that closely resemble final products.

Example: Real-World Use Case of Digital Manufacturing

Consider an automotive parts manufacturer developing a new engine component. In a traditional setup, the design would go through multiple manual revisions before production. With digital manufacturing:

- Engineers create a 3D CAD model

- The model is digitally simulated for stress and performance

- A CNC machine produces a rapid prototype

- Data from the prototype is analyzed and improved

- Final production begins without redesigning the part

Benefits of Digital Manufacturing for CNC Machining and Rapid Prototyping

Digital manufacturing offers several advantages that are reshaping the industry.

1. Faster Time to Market

Products can be designed, tested, and produced much faster due to automation and digital simulations.

2. Improved Accuracy and Precision

CNC machines guided by digital data deliver tight tolerances and consistent quality.

3. Cost Efficiency

Early error detection reduces material waste and lowers production costs.

4. Better Collaboration

Designers, engineers, and manufacturers work on the same digital platform, reducing miscommunication.

5. Scalability

Prototypes can be easily converted into mass production without starting from scratch.

Common Mistakes Manufacturers Make

Despite its advantages, many businesses fail to fully benefit from digital manufacturing due to common mistakes.

1. Poor Software Integration

Using disconnected CAD, CAM, and CNC systems breaks the digital workflow.

2. Lack of Skilled Workforce

Advanced tools require trained operators and engineers.

3. Ignoring Data Analytics

Collecting machine data without analyzing it leads to missed optimization opportunities.

4. Over-Automation Without Planning

Automation without proper strategy can increase costs instead of reducing them.

5. Not Updating Legacy Systems

Old machines that cannot integrate with digital platforms slow down production.

Conclusion

Digital manufacturing is fundamentally reshaping CNC machining and rapid prototyping by making manufacturing smarter, faster, and more efficient. From automated CNC machines to data-driven prototyping, the entire production lifecycle is now digitally connected. Businesses that adopt digital manufacturing gain a competitive edge through reduced costs, improved quality, and faster innovation. However, success depends on proper planning, skilled teams, and seamless system integration. As technology continues to evolve, digital manufacturing will become the standard rather than the option. Manufacturers who embrace this transformation today will be the leaders of tomorrow.

I and my wife stood amazed. Then I realised that the crest of Maybury Hill must be within range of the Martians’ Heat-Ray now that the college was cleared out of the way.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Fusce vitae tortor varius, blandit turpis nec, condimentum ipsum. Maecenas augue augue, maximus sed gravida a, consequat sed lectu