Automation is transforming industries at an incredible pace. From robots assembling cars to algorithms managing supply chains, machines are doing tasks once handled entirely by humans. But despite these advancements, automation is not replacing people—it is reshaping how humans and machines work together. The surprising truth is that even in highly automated environments, human involvement remains critical. Whether it’s handling delicate items like bananas, ensuring the quality of luxury products like champagne, or managing intelligent robots on factory floors, automation still depends on human judgment, creativity, and adaptability. This article explores why automation cannot fully function without humans, how human skills complement robotic efficiency, and what this collaboration means for the future of work.

Main Concept: Human–Machine Collaboration in Automation

Automation is often misunderstood as a complete replacement for human labor. In reality, modern automation works best when humans and machines collaborate rather than compete.

Explanation: Why Automation Alone Is Not Enough

Robots and automated systems excel at repetitive, rule-based, and high-speed tasks. They are precise, consistent, and capable of working continuously without fatigue. However, they struggle with tasks that require:

- Complex decision-making

- Emotional intelligence

- Creativity and innovation

- Handling unpredictable situations

For example, a robot can sort objects based on size and weight, but identifying a bruised banana or detecting subtle defects in champagne bottles often requires human perception. Automation systems rely heavily on predefined rules and data, while humans excel at adapting to change.

This is why industries are moving toward augmented automation, where machines handle efficiency and humans provide oversight, judgment, and improvement.

Example: Bananas, Champagne, and Robots in the Real World

The food and beverage industry offers excellent examples of why humans are still essential.

Bananas:

Automated systems can harvest and package bananas, but assessing ripeness, texture, and minor damage is still more accurately done by human workers. A robot may detect size differences, but it often misses subtle quality issues.

Champagne:

Luxury champagne production relies on craftsmanship. While robots assist with bottling and labeling, humans control fermentation, taste testing, and final quality approval. Automation supports consistency, but humans protect brand value.

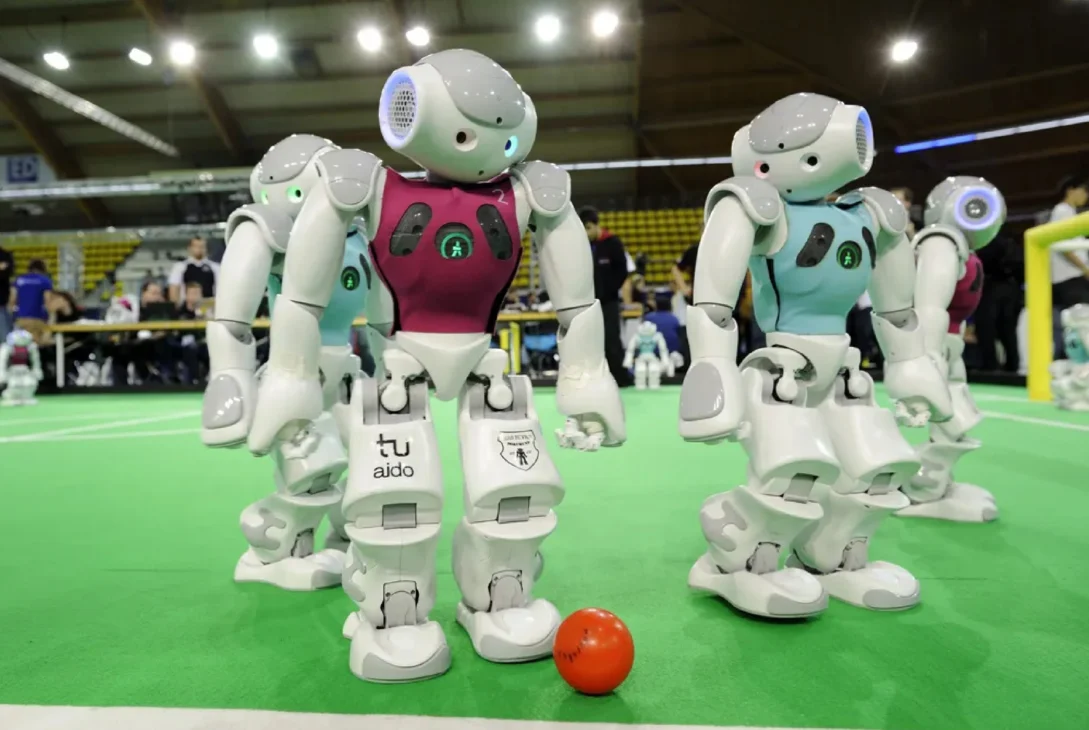

Robots in Manufacturing:

In smart factories, robots assemble components while humans program machines, monitor performance, and troubleshoot errors. Without human supervision, even the smartest robots can fail when unexpected issues arise.

These examples show that automation increases efficiency—but humans ensure quality and reliability.

Benefits of Keeping Humans in Automated Systems

Combining automation with human involvement offers powerful advantages across industries.

1. Better Quality Control

Humans can identify defects, inconsistencies, and anomalies that machines may overlook.

2. Flexibility and Adaptability

When processes change or unexpected problems occur, humans can respond faster than automated systems.

3. Innovation and Improvement

Machines follow instructions, but humans create new ideas, optimize workflows, and improve systems over time.

4. Ethical and Safety Oversight

Human decision-making ensures automation aligns with ethical standards, safety regulations, and customer expectations.

5. Increased Trust and Reliability

Customers trust products more when human expertise plays a role, especially in food, healthcare, and luxury goods.

Common Mistakes Companies Make with Automation

Despite automation’s potential, many organizations make errors that limit its success.

1. Assuming Full Automation Is the Goal

Trying to remove humans entirely often leads to quality issues and system failures.

2. Underestimating Human Skills

Companies sometimes ignore the value of experience, intuition, and problem-solving abilities.

3. Poor Training Programs

Without proper training, employees cannot effectively manage or improve automated systems.

4. Over-Reliance on Data

Data is powerful, but it cannot always capture real-world complexity or human behavior.

5. Ignoring Human–Machine Design

Automation systems designed without considering human interaction often create inefficiencies instead of solving them.

Conclusion

Automation is revolutionizing the way we work, but it is not eliminating the need for humans. From handling delicate bananas to protecting the quality of champagne and managing intelligent robots, human skills remain irreplaceable. The future of automation lies in collaboration, not replacement. Machines bring speed and precision, while humans contribute creativity, judgment, and adaptability. Companies that recognize this balance will achieve better efficiency, higher quality, and long-term success. In the end, automation works best not when humans are removed—but when they are empowered.